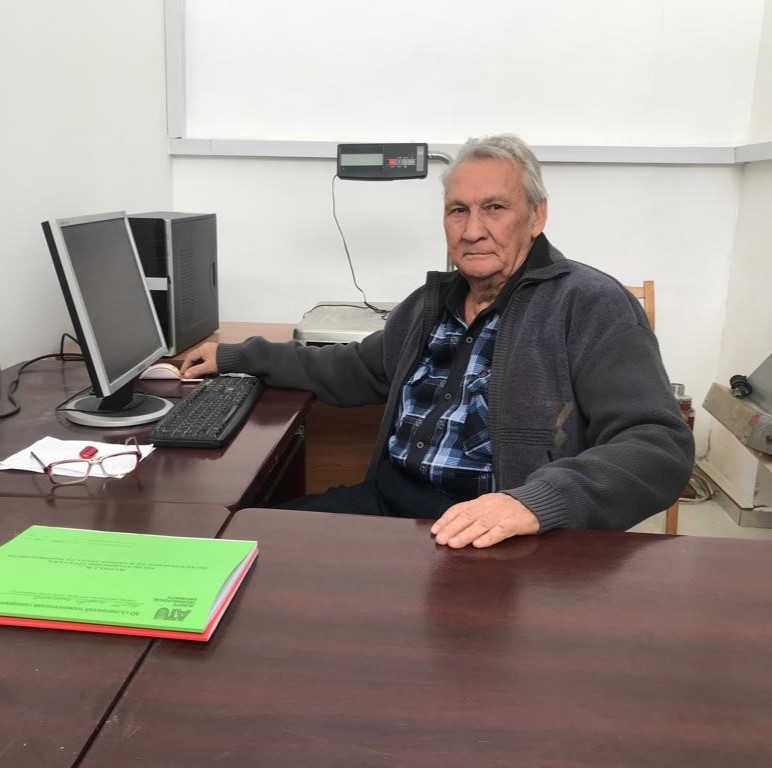

Director of SRIFT

Iztayev Auyelbek

Doctor of technical sciences, professor Academian NASc RK

Phone.: 396-71-33 (ext. 125)

E-mail: a.iztaev@atu.kz

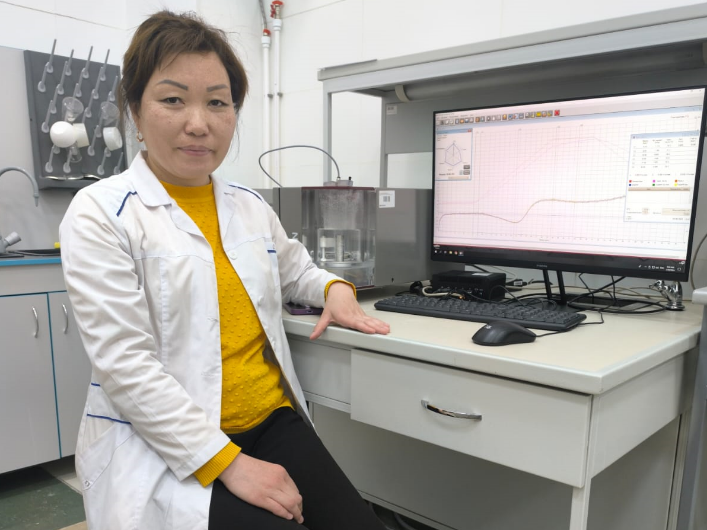

Deputy Director of RIFT

Yakiyayeva Madina

PhD, associate professor

Phone.: 276-88-60

E-mail: m.yakiyayeva@atu.kz, niipt@atu.kz

Research Institute of Food Technologies (RIFT)

structural scientific division of the university, which is part of the Science Directorate, carrying out fundamental and applied research in a wide range in the field of food and processing industries.

The main priority areas of scientific activity of the Institute:

SCIENTIFIC-RESEARCH LABORATORY «RHEOLOGY OF FOOD PRODUCTS»

Scientific-Research Laboratory «Rheology of Food Products is a structural unit of the Scientific Research Institute of Food Technologies of JSC "ATU". The laboratory conducts both fundamental and applied research in the field of studying the rheological properties of food products, including bakery products and plant-based foods. The main focus is on developing technologies to improve the texture, consistency, and other rheological characteristics of products based on legumes, oilseeds, vegetables, and fruits used in the food industry of the Republic of Kazakhstan.

Main Scientific Directions of the Laboratory:

Research on accelerated preparation technologies for frozen dough enriched with plant-based ingredients and the changes in their rheological properties.

Development of resource-saving technologies for processing grain and other agricultural crops with improved textural and viscosity properties, including the use of non-traditional raw materials rich in fiber.

Study of new types of functional food products with improved rheological parameters.

Development of new formulations of yeast-free bread and bakery products with enhanced texture and consistency.

Research of rheological properties of flour made from domestic triticale varieties: analysis of consistency, viscosity, elasticity, and other textural characteristics of flour, which is important for developing accelerated technologies. Study of the effects of various factors (moisture, temperature, kneading time) on the rheological parameters of dough.

Determination of optimal kneading and proofing conditions: in the context of yeast-free technology, it is important to study how the rheological properties of dough change with various processing methods, such as the use of alternative leavening agents and improvers.

Development of an accelerated dough formation and baking process: based on the analysis of rheological properties, a method will be proposed for the rapid and efficient preparation of dough, ensuring the desired consistency and structure of the final products.

Quality assessment of yeast-free bakery products: using texture analysis methods and other rheological tests, research will be conducted aimed at improving the consistency, porosity, and taste characteristics of the products.

Determination of rheological and strength characteristics of raw materials and semi-finished products using the texture analyzer Structurometer ST-2

SCIENTIFIC-RESEARCH LABORATORY OF TECHNOLOGIES FOR FOOD AND PROCESSING INDUSTRIES

E-mail: yerkinkz@rambler.ru

E-mail: mister_almaz89@mail.ru

The «Scientific-research laboratory of technologies for food and processing industries» carries out fundamental and applied scientific research, the development of science-intensive projects in the interests of developing the economy and ensuring food and food security of the country, the introduction of modern innovative technologies that ensure high safety of raw materials to create a new range of food products that meet environmental food safety requirements. The laboratory implements a large scientific direction on the development and implementation of ion-zone technology for processing, storing and processing grain in the field of electromagnetic cavitation at elevators and grain processing enterprises.

The main scientific direction of the laboratory:

The main achievements of the laboratory:

Director of RIFT

Deputy Director of RIFT

Laboratory manager

Laboratory Engineer